🖨 Copper Damascus Hunter Knife: Hand-Forged 1095 & Copper Steel Masterpiece

Experience the ultimate blend of artistry and performance with the Ansari Forge Copper Damascus Hunter Knife. Hand-forged from a unique composition of high carbon 1095 steel, 15N20 nickel steel, and 99.9% pure copper, this full-tang, fixed-blade knife features a striking clip point and 512 true layers. With a robust 60 HRC hardness and a comfortable black micarta handle, this is the Best fixed blade hunting knife for collectors and serious outdoorsmen alike.

The Hunter’s Choice: Unveiling the Copper Damascus Knife

Are you searching for a reliable, high-performance fixed blade that is as stunning as it is functional? The Ansari Forge Hunter Knife is meticulously hand-forged to exceed the expectations of hunters, survivalists, and knife enthusiasts. Our unique integration of copper into the Damascus pattern creates a breathtaking finish that makes this a true collector’s item and the ultimate Copper Damascus knife.

Unrivaled Blade Quality and Craftsmanship

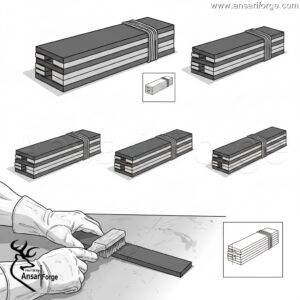

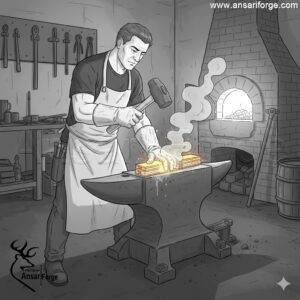

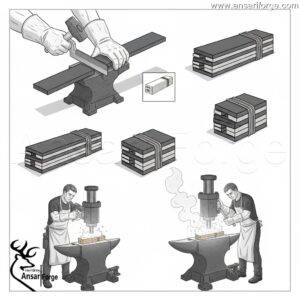

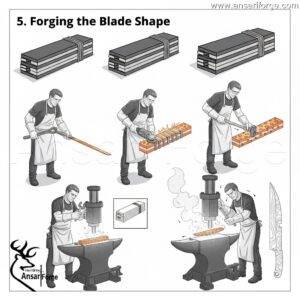

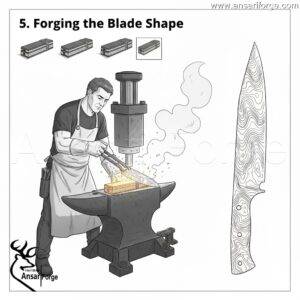

The core of this exceptional tool is its blade, a work of art created through expert forge-welding:

- Copper Damascus Steel: We combine premium high carbon 1095 steel and 15N20 nickel steel, folding them with 99.9% pure copper. This results in a mesmerizing, one-of-a-kind pattern and provides outstanding edge retention and durability.

- 512 True Layers: The high layer count ensures maximum strength and showcases the depth of the Damascus pattern.

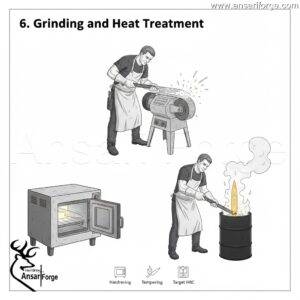

- Optimal Hardness: Heat-treated to a rock-solid 60 HRC hardness, guaranteeing a razor-sharp edge that lasts through demanding use.

- Blade Profile: The classic clip point design is versatile, offering a strong tip for piercing and a generous belly for slicing tasks.

- Dimensions: A formidable 7.5-inch blade length paired with a spine thickness of 5.0 mm for heavy-duty performance.

Built for Comfort and Durability – Copper Damascus Knife

The quality extends beyond the blade to the entire construction, ensuring reliable use in any environment:

- Full-Tang Construction: A single piece of steel runs the entire length of the knife, providing unmatched strength and balance. This is essential for a Damascus steel knife hunting in the wilderness.

- Ergonomic Handle: The durable black micarta handle offers a secure, comfortable, and non-slip grip, even when wet.

- Damascus Guard: A matching Damascus guard protects your hand and enhances the overall aesthetic.

- Perfect Balance: With a handle length of 4.5 inches and an overall length of 12.0 inches, the knife is perfectly balanced for control and powerful cutting.

Premium Presentation and Protection

Every Ansari Forge Hunter Knife comes complete with a high-quality sheath:

- Genuine Cowhide Leather Sheath: Hand-stitched and custom-fitted, this durable sheath offers secure carry and superior protection for your blade in the field.

Specifications

| Feature | Detail |

|---|---|

| Product Name | Copper Damascus Hunter Knife |

| Manufacturer | Ansari Forge |

| Steel Composition | 1095 High Carbon, 15N20 Nickel, 99.9% Pure Copper |

| Layer Count | 512 Layers |

| Hardness (HRC) | 60 HRC |

| Blade Style | Clip Point |

| Construction | Full Tang |

| Blade Length | 7.5 inches |

| Handle Material | Black Micarta |

| Handle Length | 4.5 inches |

| Overall Length | 12.0 inches |

| Spine Thickness | 5.0 mm |

| Sheath | Genuine Cowhide Leather |

| Primary Use | Hunting, Bushcraft, Collection |

Why Choose the Ansari Forge Hunter Knife?

- Unique Aesthetics: The copper-infused Damascus pattern is unlike anything else on the market.

- Lifetime Durability: Built to be the Best fixed blade hunting knife you will ever own.

- Superior Value: Expert hand-forging at a competitive price point.

- Ready to Use: Comes razor-sharp and includes a premium sheath.

Click ‘Add to Cart’ now and own a piece of functional art! Experience the difference of a genuine Damascus steel knife hunting companion.

While the exact forging methods of the original, ancient steel (often referred to as "Wootz" steel) have been lost to history, modern Damascus steel is created using a technique called

While the exact forging methods of the original, ancient steel (often referred to as "Wootz" steel) have been lost to history, modern Damascus steel is created using a technique called

There are no reviews yet.